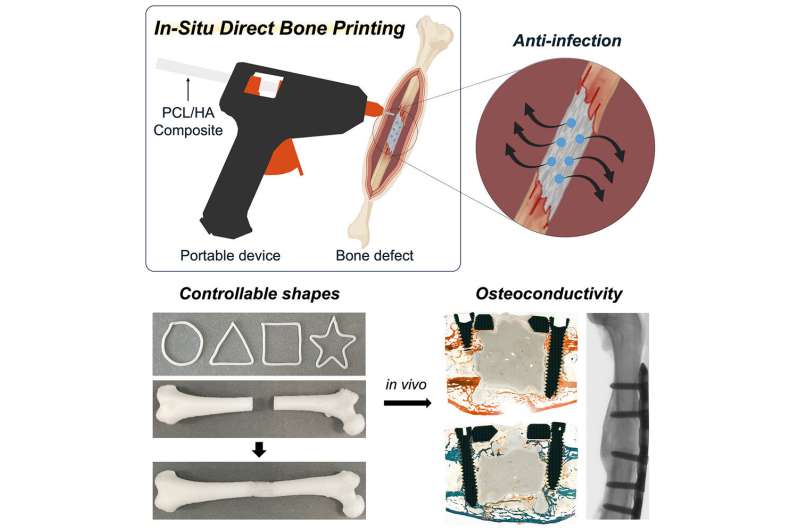

The tool, described in the journal Device, has been tested in rabbits to quickly create complex bone implants without the need for prefabricating in advance. What’s more, the team optimized the 3D-printed grafts for high structural flexibility, release of anti-inflammatory antibiotics, and promotion of natural bone regrowth at the grafting site.

Historically, bone implants have been made of metal, donor bone, or even more recently, 3D-printed material. However, in cases involving irregular bone breaks, these implants must be designed and produced prior to surgery to allow for appropriate fitting.

“Our proposed technology offers a distinct approach by developing an in situ printing system that enables a real-time fabrication and application of a scaffold directly at the surgical site,” says Jung Seung Lee, co-author and associate professor of biomedical engineering at Sungkyunkwan University.