Boston Micro Fabrication (BMF), a leader in advanced manufacturing solutions for ultra-high precision applications, has announced it has received U.S. Food and Drug Administration (FDA) 510(k) clearance for its UltraThineer material used to create the ‘world’s thinnest’ cosmetic dental veneer.

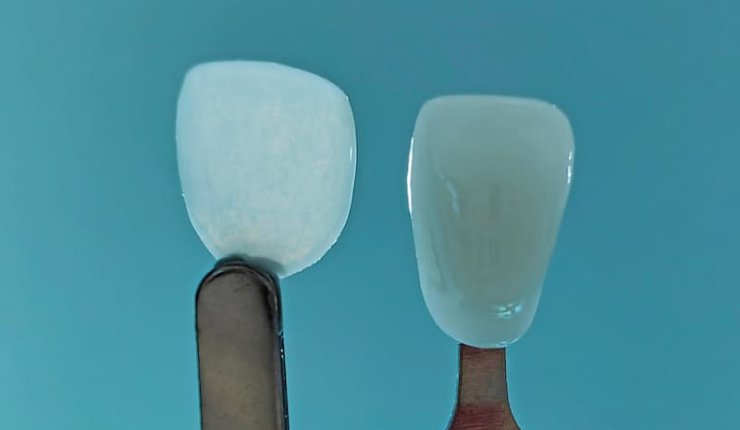

The new 3D printed veneers use projection micro stereolithography (PµSL), a technology that allows for greater resolution, accuracy and precision, to custom-manufacture veneers that are three-times thinner than traditional veneers. Further, UltraThineer requires significantly less preparation for dental professionals, allowing preservation of the patient’s original enamel with a more realistic final appearance.

“We are thrilled to hear that the UltraThineer veneer has received FDA 510(k) clearance. This is a significant milestone for our industry as having the ability to 3D print veneers in Zirconia is a game changer for dental technology. This breakthrough allows us to offer patients high quality veneers that require minimum prepping. This is just the beginning of our journey to revolutionize dental care, and we look forward to working with BMF to begin offering the UltraThineer to dental patients across the country,” said Dany Karam, President, Advanced Dental Technologies.

According to BMF, UltraThineer veneers are the world’s thinnest veneers and feature advanced material, a production workflow, and the finishing process to deliver more comfortable and less invasive options in cosmetic dentistry.