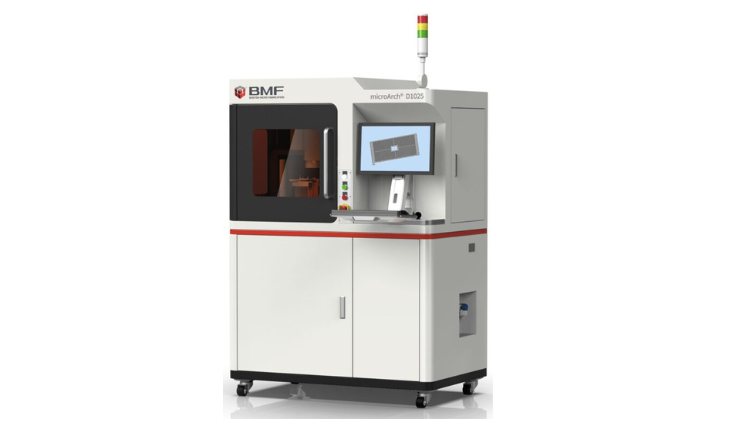

To offer more flexibility for customers looking for high precision 3D printing solutions, Boston Micro Fabrication (BMF) is launching what it says is the industry’s first line of hybrid printing solutions for micro-scale and ultra high-resolution applications. The dual resolution microArch D1025 is the first printer in the series, printing in either 10µm or 25µm resolution, or in hybrid mode with both resolutions in the same print layer or in different layers.

Built upon BMF’s patented Projection Micro Stereolithography (PµSL) technology, the microArch D1025 enables more efficiency within the 3D printing process according to the company, allowing users across healthcare, electronics, life sciences, and photonics applications to print two resolutions within a single layer.

Using a technique that allows for rapid photopolymerisation of layers of liquid polymer using a flash of UV light at micro-scale resolution, the 25µm resolution mode can be used for parts in which the features don’t require ultra-high resolution and 10µm mode supports small, complex features to optimise the 3D printing process. Users also have the ability to choose to print a single build in either 25µm or 10µm depending upon the part geometry, providing greater flexibility and efficiency across all applications and industries.