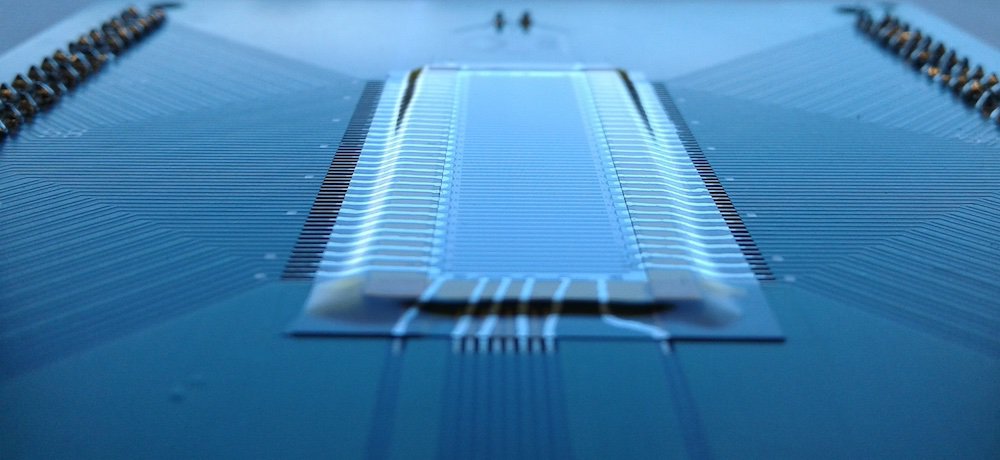

The company is developing and commercialising an ultrasound technology that utilises polymer MEMS sensors to send and receive ultrasonic waves. Their transducers are empowered by the innovative polyCMUT technology (stands for polymer-based Capacitive Micromachined Ultrasound Transducers). This method of manufacturing ultrasonic transducer arrays involves crafting thousands of vibrating micro-drums on different types of substrate. The polyCMUT offersenhanced imaging capabilities and a new standard for diagnostic and material testing.

Dr. Hani Eskandari, CEO and president at Sonus Microsystems, said: “We are uniquely positioned with over 100 years of ultrasound domain expertise to deliver our cutting-edge customisable ultrasound transducers which enable automated imaging for remote monitoring and wearable ultrasound applications powered by AI diagnosis.”

The company specialises in manufacturing ultrasound transducers tailored for three distinct use cases: disposable and miniature transducers ideal for applications demanding high-quality imaging in limited spaces; flexible and cost-efficient wearable transducers that unlock various healthcare monitoring and screening applications; and large matrix array transducers, offering operator-independent ultrasound imaging for remote monitoring and screening across diverse use cases. Sonus’s novel matrix technology is paving the way for accessible AI-powered patches that automate ultrasound scanning and measurement and unlock affordable monitoring and screening of patients.