How the new sensor technology works

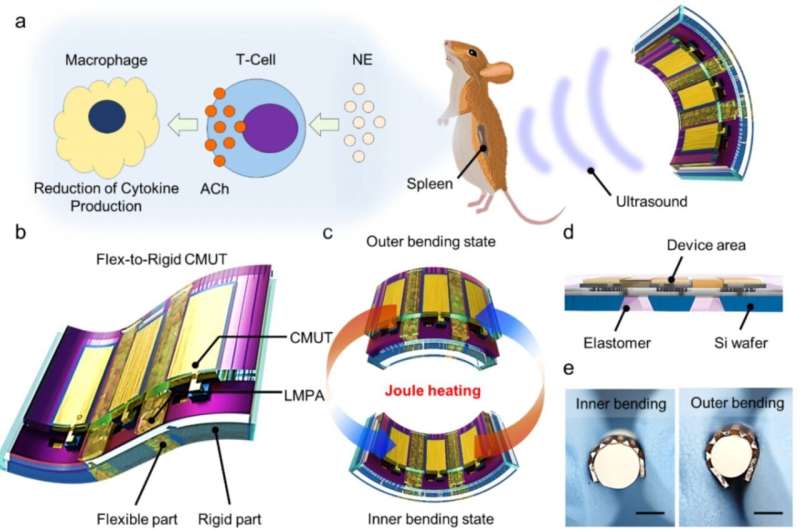

The research team led by Professor Hyunjoo Jenny Lee from the School of Electrical Engineering developed a “flex-to-rigid (FTR)” capacitive micromachined ultrasonic transducer (CMUT) capable of transitioning freely between flexibility and rigidity using a semiconductor wafer process (MEMS).

The results are published in npj Flexible Electronics.

The team incorporated a low-melting-point alloy (LMPA) inside the device. When an electric current is applied, the metal melts, allowing the structure to deform freely; upon cooling, it solidifies again, fixing the sensor into the desired curved shape.